- info@fomeco.vn

- Business hours: Mon-Fri from 07:30 AM to 04:30 PM

- ISO 9001 : 2015; IATF 16949 : 2016; ISO 14001 : 2015; ISO 50001 : 2018

- Thái Nguyên, Việt Nam

- (+84) 2083 863 694

Tin tức mới

Tin cổ đông

Về chúng tôi

CÔNG TY CỔ PHẦN CƠ KHÍ PHỔ YÊN

Công ty cổ phần cơ khí Phổ Yên (FOMECO) tự hào nằm trong top các doanh nghiệp dẫn đầu về gia công cơ khí chính xác tại Việt Nam.

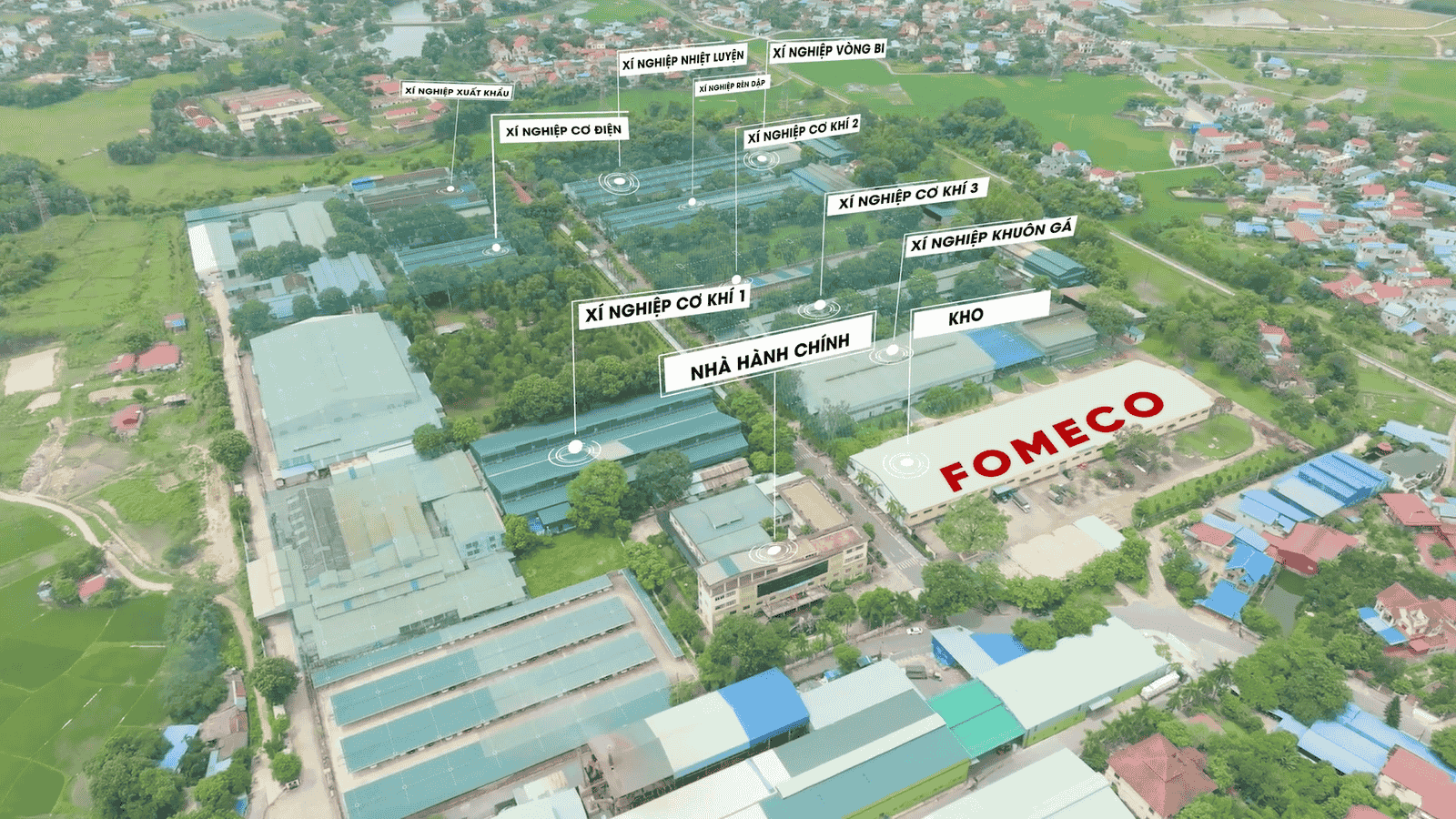

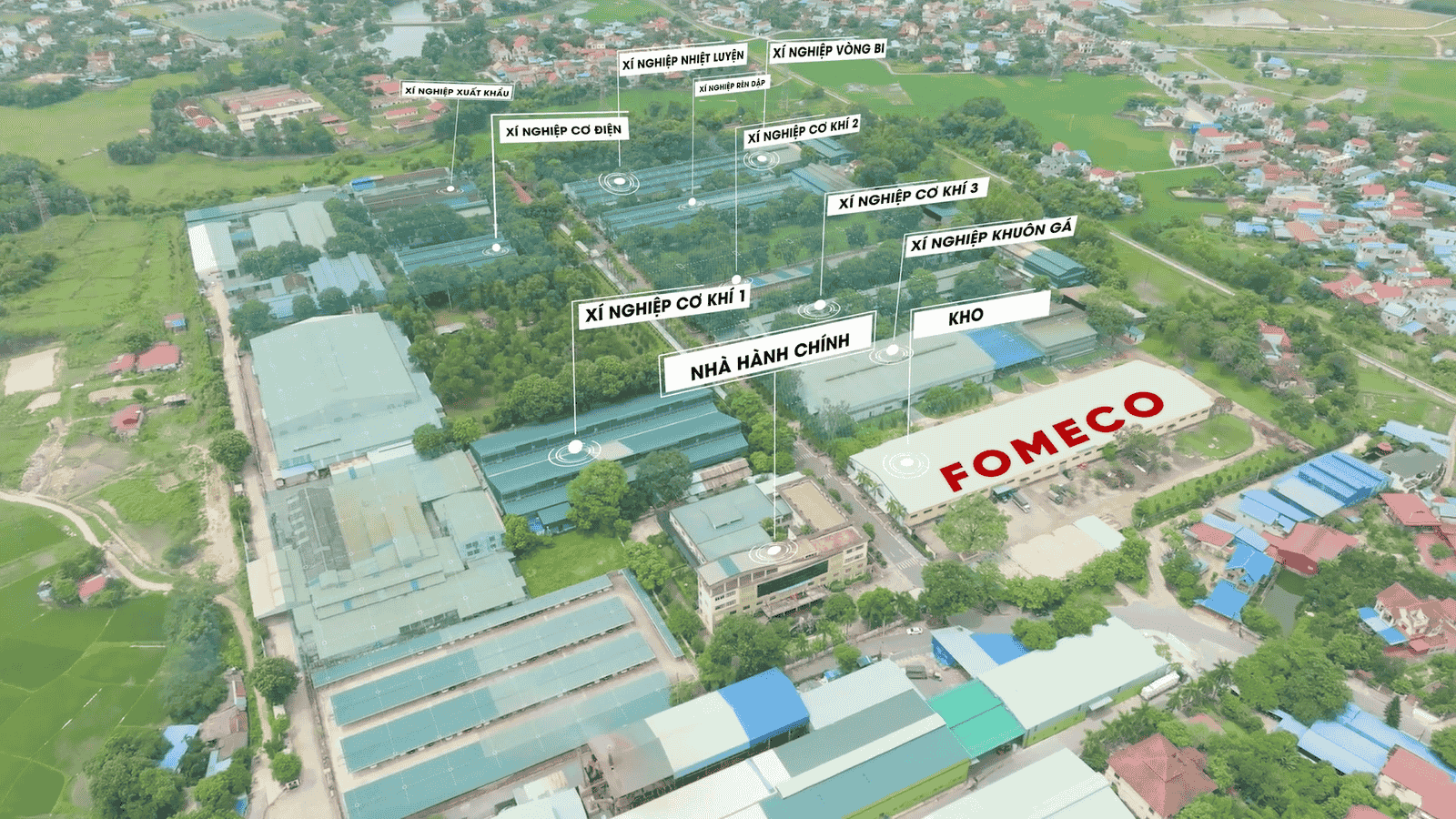

Trụ sở chính của công ty đặt tại phường Bãi Bông, thành phố Phổ Yên, tỉnh Thái Nguyên, cách thủ đô Hà Nội khoảng 50km, sân bay quốc tế nội bài 34km, cảng Hải Phòng 180km. Công ty còn có văn phòng đại diện được đặt tại Quận Bình Tân, thành phố Hồ Chí Minh.

Chúng tôi cung cấp sản phẩm cho thị trường đa dạng nhóm ngành từ linh kiện đơn lẻ tới cụm chi tiết bao gồm phụ tùng xe máy, phụ tùng ô tô, các loại vòng bi, phụ tùng cho máy nông nghiệp và máy công trình, phụ tùng cơ khí cho ngành xây dựng.

Trải qua 50 năm phát triển, với bề dày kinh nghiệm và thành tựu, chúng tôi tự hào hợp tác với nhiều đối tác lớn, không ngừng mở rộng mạng lưới phân phối và nâng cao chất lượng dịch vụ. Sản phẩm của Fomeco không chỉ cung cấp cho thị trường bán lẻ nội địa, và các doanh nghiệp FDI như Honda, Yamaha, Piaggio, mà còn xuất khẩu sang các thị trường quốc tế như Hoa Kỳ, Châu Âu, Nhật Bản, Trung Quốc.

Công ty đã tạo được uy tín lớn trên thị trường với các sản phẩm có chất lượng ổn định, giá thành hợp lý thông qua việc tuân thủ chặt chẽ hệ thống quản lý chất lượng ISO 9001-2015, ISO 14001-2015, ISO IATF 16949-2016 và ISO 50001-2018.

hành trình 50 năm phát triển

Hành trình đáng tự hào bắt đầu từ ngày 19/10/1974, “Nhà máy Cơ khí Phổ Yên” tiền thân của Công ty Cổ phần Cơ khí Phổ Yên ngày nay được thành lập.

Từ những ngày đầu, với những phân xưởng sản xuất nhỏ, thiết bị viện trợ đã cũ kỹ, cơ cấu sản phẩm đơn điệu chỉ gồm các loại vòng bi, phụ tùng máy nông nghiệp, dụng cụ, con lăn băng tải, cung cấp cho các doanh nghiệp quốc doanh, đến nay, công ty đã vươn mình lớn mạnh, nằm trong top các doanh nghiệp dẫn đầu về gia công cơ khí chính xác tại Việt Nam.

Trong 50 năm qua, với quyết tâm và sáng tạo trong điều hành, công ty đã không ngừng đổi mới, phát triển, sản xuất kinh doanh tăng trưởng liên tục qua các năm, tạo được vị thế vững chắc trên thị trường trong và ngoài nước. Công ty không ngừng phát triển các sản phẩm hết sức đạ dạng về công nghệ, có hàm lượng chất xám cao, có cấu sản phẩm đa dạng từ vòng bi, phụ tùng xe máy, phụ tùng máy nông nghiệp, máy công trình, phụ tùng cơ khí cho ngành xây dựng, đến phụ tùng ô tô.

Công ty chú trọng đầu tư về công nghệ, trang thiết bị hiện đại, tự động hoá cao. Đến nay, công ty đã làm chủ quy trình công nghệ đồng bộ khép kín đáp ứng các công nghệ từ tạo phôi trên thiết bị dập nóng, dập nguội; Gia công CNC; Xử lý nhiệt trên dây chuyền tự động, xử lý nhiệt nhôm; Xử lý bề mặt trên dây chuyền mạ kẽm nhúng nóng, và dây chuyền sơn phủ khác.

Fomeco tự tin có thể đáp ứng được những đòi hỏi khắt khe nhất từ khách hàng.

ĐỐI TÁC của chúng tôi